Crude Oil refining and petrochemicals productions are essential for global economies and our modern-day societies. Petrochemicals are chemical substances made from petroleum and natural gases. They can also be found in plastics, rubber, cosmetics, nylons, and medical supplies.

The refining process

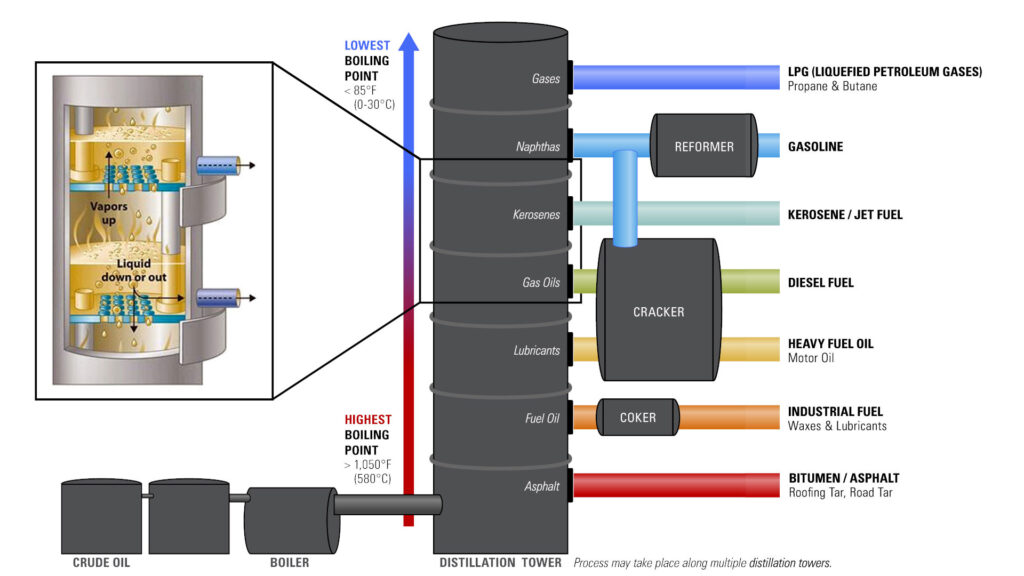

Oil refining is the transformation and refining of crude oil into useful products such as petroleum naphtha, gasoline, diesel fuel, asphalt base, fuel oils, heating oil, kerosene, and liquefied petroleum gas.

The process of oil refining is crucial in petrochemical production. Petrochemicals are chemical substances made from crude oil (petroleum) and natural gases that produce petrochemical products, including ethylene, propylene, and benzene.

After crude oil (petroleum) is transformed at the oil refineries, the outcome of the process is raw materials or feedstock, such as naphtha, that are used to produce petrochemicals combined with natural gases.

Petrochemical production

Petrochemical refining takes place after oil refining, as petrochemical products are obtained from petroleum refining. Refining processes are used mainly in petroleum refineries. Petrochemical facilities are not necessarily refineries, although they may include them. Refining crude oil can take place outside of a petrochemical plant.

The basic crude oil refining process includes distillation, cracking, reforming, blending, and treatment.

- Distillation refers to the separation of heavy and lighter fossil fuels.

- Cracking comprises maximizing the use of heavy oils by breaking them into more valuable lighter fluids.

- Reforming involves leveraging the amount of gasoline produced from crude oil by rearranging the molecules in the produced chemicals into other useful ones, such as gasoline.

- The blending process mixes the refinery products to obtain finished petroleum fuels. For example, gasoline is blended to achieve octane standards to meet specific engine needs.

- The final process of treating petroleum products involves removing toxic chemicals like sulfur from gasoline and other products and ensuring safe product use and distribution.

The combination of a treatment facility and petrochemical complex suggests distinguishing collaborations and improving them for functional and monetary increases where they offer and trade many streams like feedstocks, results, and utilities. Integrating refining and petrochemicals provides optimal molecule management for a better return on investment. Treatment facilities have generally been pointed toward leveraging fuels as end-products and simultaneously using open doors for separating higher worth.